Categories: PLASTIC WELDING TOOLS, Tools & Welding>

ROLLERS

ROLLERS

Essential Support for Seamless Butt Fusion Welding

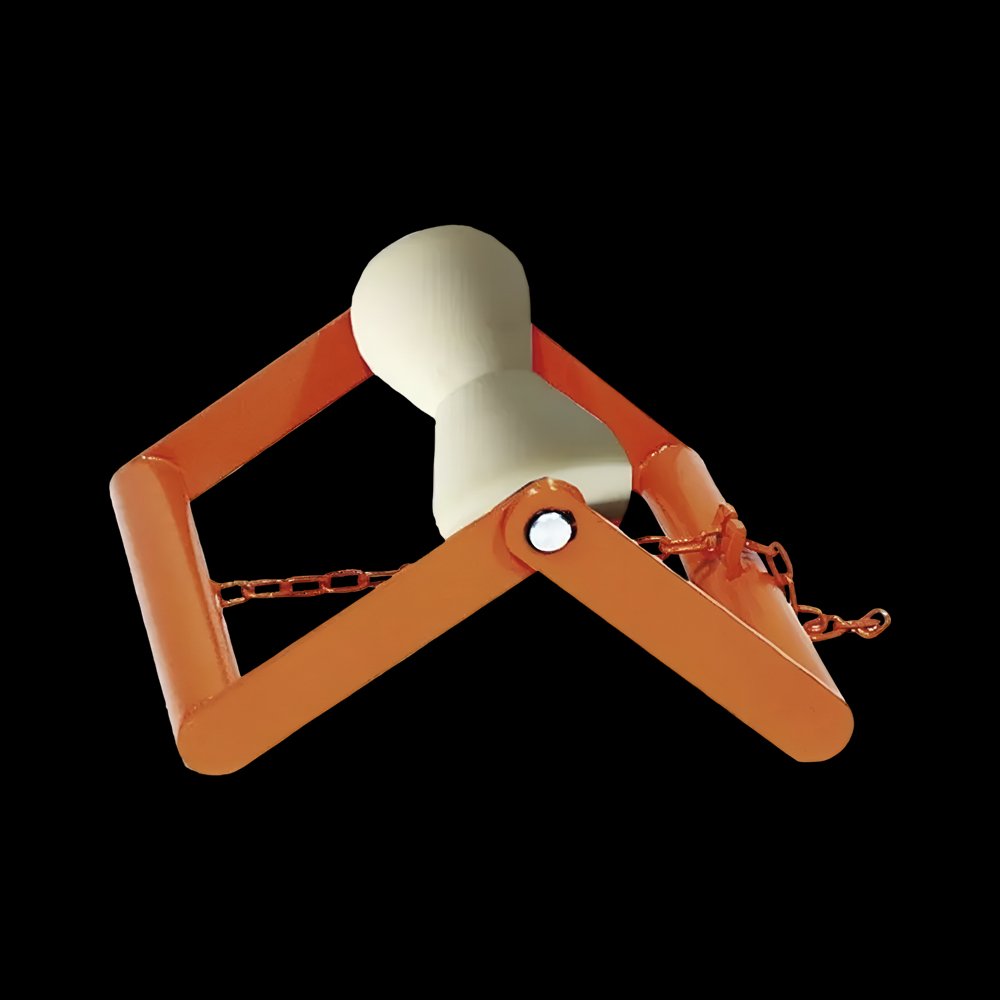

Ensure precision and efficiency during pipe welding with our ROLLERS , a must-have accessory for supporting pipes while using butt fusion machines. Designed to minimize friction and drag force, these rollers provide smooth, consistent movement of the pipe, regardless of challenging site conditions. Whether you’re working on small-scale projects or large industrial installations, our rollers are engineered to deliver reliable performance and ease of use.

Why Choose Our Rollers?

- Smooth Operation: The rollers reduce pipe friction and drag, allowing for effortless alignment and movement during welding.

- Lightweight & Portable: Each model is designed to be lightweight, making transportation and setup hassle-free, even in remote or hard-to-reach locations.

- Versatile Working Range: Available in three models to accommodate a wide range of pipe sizes:

- ROLLER 315: Supports pipes up to 315mm in diameter. Compact, easy to use, and perfect for smaller projects.

- ROLLER 560: Supports pipes up to 560mm in diameter. Offers excellent stability and ease of handling for medium-sized applications.

- ROLLER 1000: Supports pipes from 315mm to 1000mm in diameter. Its modular design allows for quick disassembly and reassembly, enabling storage of up to eight rollers on a single pallet for improved logistics and transport efficiency.

- Advanced Features:

- Misaligned Rollers: Strategically designed to allow easy movement of pipes, even in the presence of weld beads, ensuring uninterrupted workflow.

- Modular Design (ROLLER 1000): Quick assembly and disassembly make it ideal for storage and transport, saving space and reducing costs.

Key Benefits:

- Durability: Built to withstand demanding job site environments while maintaining optimal performance.

- Ease of Use: Lightweight construction and simple operation ensure that even novice users can handle the rollers with confidence.

- Improved Logistics: The ability to store multiple ROLLER 1000 units on a single pallet streamlines transportation and reduces logistical challenges.

- Enhanced Productivity: By minimizing friction and drag, these rollers help speed up the welding process, saving time and labor costs.

Applications:

Our rollers are perfect for a variety of industries, including:

- Plumbing and pipeline construction

- Industrial piping systems

- Water and wastewater management

- Gas distribution networks

Technical Specifications:

- ROLLER 315: Supports pipes up to 315mm , lightweight, and easy to carry.

- ROLLER 560: Supports pipes up to 560mm , lightweight, and user-friendly.

- ROLLER 1000: Supports pipes from 315mm to 1000mm , modular design, easy to disassemble and reassemble, and capable of storing up to eight units on a single pallet.

| Model | Working Range | Dimension(mm) | Weight(kg) |

|---|---|---|---|

| Light Weight Unit | Max 315mm | 400*290*240 | 6.00 |

| 560 Unit | Max 560mm | 900*690*450 | 65.00 |

| 1600 Unit | Max 1600mm | 920*730 520 | 76.00 |